An Introduction to Wright Tools

Few things are more inspiring than an old fashioned American “rags to riches” success story and while the founder of Wright Tools didn’t exactly start with rags, this story is definitely not one that’s common anymore as it involves hard work, dedication, opportunity and more than a little initiative. After selling tools out of the back of his car for what he probably felt was an adequate amount of time, founder C. Nelson Wright founded Wright Tool & Forge Company in 1927. With a focus on hometown American manufacturing in Ohio, Wright Tools grew to become an international presence, particularly for automotive and industrial use. They have a long and interesting history with some unique milestones, like making one of the first cushion grip handles, that you can explore here and here. This history also includes an identity crisis phase in the late 50’s where they made nothing but sockets. Thankfully they grew out of it. In all this time Wright Tools has become more polished and refined when compared to the examples from 100 years ago, but you can clearly see that the one thing that hasn’t changed is dedication to quality.

Throughout their existence, Wright has kept their manufacturing here in America where they infuse the pioneering American spirit into every tool that’s forged and they have a saying that goes “wherever a hard job is being done you’ll find a Wright Tool working on it” demonstrating their drive for quality. This is why Wright has made tools used working in the mining, oil & gas, and commercial construction industries among many more. Some of Wright’s tools were also used to construct the Hoover Dam and have also been used in space with NASA’s Orion Space Program.

Jobs probably don’t get much harder than that.

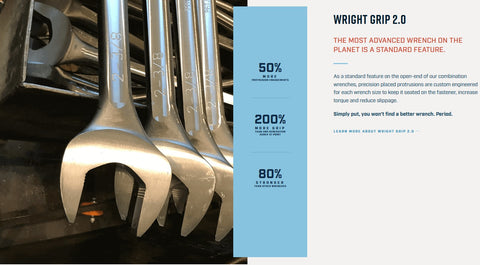

So, what makes a Wright tool so tough? A mix of staying true to longtime standards of quality while also incorporating innovations, such as the Wright Grip 2.0 and the Wright Drive 2.0 for added grip, constantly improving designs and overall tool quality. Over the years, Wright has developed a proprietary steel alloy and has fine-tuned their hot forging process to make some of the toughest tools on the planet even tougher with precision heat treating. They’re so confident in their workmanship they’ve adopted the slogan “you’ll break before our tools do.” This quality mindset is so ingrained in Wright’s culture that the new, fourth president of Wright Tools (instated in 2021) reaffirmed Wright’s dedication to quality and preserving their brand. In addition, they continue to back up their products with a lifetime limited warranty for defects in materials and workmanship as well as providing service for certain tools like torque wrenches.

As you might expect, Wright brings this quality to bear and makes virtually any tool you might need to use, except they probably make them better. Expect to find screwdrivers, nut drivers, hex keys, pliers & snips, torque wrenches, wrenches, sockets (and attachments), hammers, punches, chisels, and many more including full tool sets and storage. Some of the sets include tools for mechanics, industrial maintenance, aircraft mechanics, and many types of service sets, all of which can be put to good use in virtually any trade.

Wright Tools has been an American treasure for nearly 100 years making many of the most commonly used tools and making them with the utmost care and quality. When you buy a Wright Tool, it’s going to be an investment into a job well done and something you can pass on to the next generation.

Leave a comment