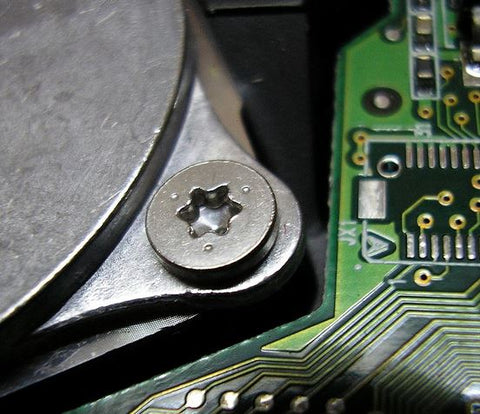

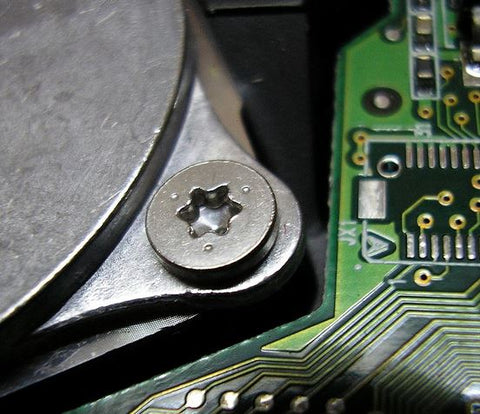

As we’ve mentioned previously, the screwdriver and screws have undergone a number of changes over the years. The key change occurred in the early 1900’s with the invention of the Phillips drive which we all know. The Phillips was designed to limit torque by “camming out” once a certain level of torque had been reached. Camming out, while reducing breakage can actually reduce the life of the tool and fastener via stripping should the cam out happen too often. To reduce cam out and extend the life of tools the Torx drive was invented. Better machining techniques and higher precision led to the development of a better torque limiting system and thus longer lasting tools and screws.

The development of the Torx screw began in 1967, was patented in 1971 and was invented by Bernard F. Reiland for the then Camcar Textron company. Technology had progressed in manufacturing to limit the amount of torque in automatic screwdrivers and since torque could be better controlled, Textron wanted to extend the life of their tools by creating a new fastener system. So, Reiland developed the Torx to add extra surface area to screws and fasteners which reduced the amount of torque applied to prevent over-torquing and thus breakage and slippage. Eliminating both of these of course extends the life of the tools and fasteners in use.

The development of the Torx screw began in 1967, was patented in 1971 and was invented by Bernard F. Reiland for the then Camcar Textron company. Technology had progressed in manufacturing to limit the amount of torque in automatic screwdrivers and since torque could be better controlled, Textron wanted to extend the life of their tools by creating a new fastener system. So, Reiland developed the Torx to add extra surface area to screws and fasteners which reduced the amount of torque applied to prevent over-torquing and thus breakage and slippage. Eliminating both of these of course extends the life of the tools and fasteners in use.

Once developed and manufactured the benefits of Torx became obvious. First and foremost, it initially helped prevent tampering. That’s less of a benefit now given that Torx drivers are pretty common, but 40+ years ago it did the job and can still be of use today in some cases. The real benefit though is that the Torx driver does what it was designed to do. We all know the frustration of using a slotted driver only to have it pop out on whim. We also probably have equal amounts of frustration with the Phillips driver camming out. Using a Torx screw and driver, by contrast, is pretty nice. It has a nice, snug fit. It doesn’t slip out, break or strip, so long as high quality, correct sized driver is used. Since their inception, Torx screws have been widely adopted and have had a lot of variations created.

Once developed and manufactured the benefits of Torx became obvious. First and foremost, it initially helped prevent tampering. That’s less of a benefit now given that Torx drivers are pretty common, but 40+ years ago it did the job and can still be of use today in some cases. The real benefit though is that the Torx driver does what it was designed to do. We all know the frustration of using a slotted driver only to have it pop out on whim. We also probably have equal amounts of frustration with the Phillips driver camming out. Using a Torx screw and driver, by contrast, is pretty nice. It has a nice, snug fit. It doesn’t slip out, break or strip, so long as high quality, correct sized driver is used. Since their inception, Torx screws have been widely adopted and have had a lot of variations created.

As manufacturing technology has improved, fastener technology has grown from the initial slotted screws to square, to Phillips and finally to Torx and beyond. Technology created the need for screws that cam out as well as a solution that dealt with torque and allowed for screws that didn’t need to escape. Torx screws have a lot of advantages and they came about at an interesting point in tool history and have grown into a staple of the home improvement industry.

Leave a comment