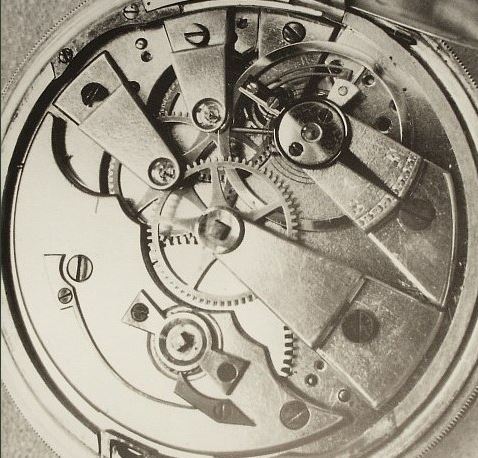

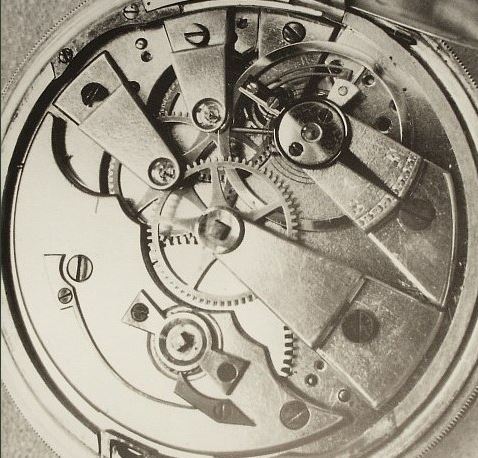

You might think that precision hand tools are a recent invention, maybe coinciding with the personal electronics boom of the 80’s and 90’s or with the more recent advent of the smartphone. Those are almost certainly catalysts in making precision hand tools accessible to the common populace and better, however if you do a little digging and put a little thought into it, you’ll realize that precision tools and engineering go back quite a bit further, probably with the clock and the pocket watch. The history of timekeeping is a long story, but by the 1500’s, clocks were an old enough technology that they were working on making them smaller and wearable. This of course needed more precision and better tools, tools which probably had origins in fine jewelry making.

There is a step-by-step build of a watch from scratch with modern tools and this craftsman employed modern tools to old methods found in old texts about watchmaking. The process would have been similar, but of course with less precise tools to work with. This should give you some idea of how antique tools were used to make fine moving parts. Early gears were probably made by hand and with great care using jeweler’s tools to cut and file the gears into a precise size and fit. Casting may have also helped once a proper piece had been crafted. These techniques along with new inventions paved the way for precise tools and pieces. The biggest game changer though was the invention of the micrometer in 1848. The micrometer allowed machinists to measure features they weren’t able to before and thus allowed them to machine smaller and smaller tools and things like gears. Additionally, the first Vernier caliper was invented in 1851 and this allowed measurement down to 1/1000 of an inch which allowed more rigorous accuracy in machined parts and allowed toolmakers like Lindström to make precision pliers and cutters in 1856. With greater precision, things could become smaller and flatter and thus more precise. Precision engineering could move beyond watchmaking and into other fields.

There is a step-by-step build of a watch from scratch with modern tools and this craftsman employed modern tools to old methods found in old texts about watchmaking. The process would have been similar, but of course with less precise tools to work with. This should give you some idea of how antique tools were used to make fine moving parts. Early gears were probably made by hand and with great care using jeweler’s tools to cut and file the gears into a precise size and fit. Casting may have also helped once a proper piece had been crafted. These techniques along with new inventions paved the way for precise tools and pieces. The biggest game changer though was the invention of the micrometer in 1848. The micrometer allowed machinists to measure features they weren’t able to before and thus allowed them to machine smaller and smaller tools and things like gears. Additionally, the first Vernier caliper was invented in 1851 and this allowed measurement down to 1/1000 of an inch which allowed more rigorous accuracy in machined parts and allowed toolmakers like Lindström to make precision pliers and cutters in 1856. With greater precision, things could become smaller and flatter and thus more precise. Precision engineering could move beyond watchmaking and into other fields.

It’s held by some that precision engineering is motivated by 1) fear, 2) greed, 3) pride and 4) inquisitiveness. The authors basically assert that profits for designing for the defense industry and the pride of making the best – whatever it is drive the move to precision. Greater precision was made possible with existing tools being used to make smaller and more precise tools for profit or the pride being the first to do it. More accurate machining made it possible to make smaller and more fine-tuned tools, fasteners and so on. As progress was made and machining techniques made things smaller and smaller, precision tools were made more and more relevant, especially once consumer electronics started to become more common.

With the appearance of the Sony Walkman in 1979, the boom of compact personal electronics required parts to be smaller as well. While not the first portable tape and music player, it was a game changer in that it was slightly more portable than its predecessors and it helped familiarize people with the idea of portable music and a plethora of wearable compact gadgets. With these small electronics and popularity of computers, it became necessary to have smaller fasteners and of course smaller and smaller tools. As the 2000’s came and we got iPods and smartphones, tools not only grew tinier, but they also grew more specialized with special heads for Torx and hex tools. While smaller tools have been around for a long time, the idea of a “precision” driver with a swivel top head for easy turning seems to be pretty recent. Klein Tools, for example, only introduced their precision tools in 2012.

With the appearance of the Sony Walkman in 1979, the boom of compact personal electronics required parts to be smaller as well. While not the first portable tape and music player, it was a game changer in that it was slightly more portable than its predecessors and it helped familiarize people with the idea of portable music and a plethora of wearable compact gadgets. With these small electronics and popularity of computers, it became necessary to have smaller fasteners and of course smaller and smaller tools. As the 2000’s came and we got iPods and smartphones, tools not only grew tinier, but they also grew more specialized with special heads for Torx and hex tools. While smaller tools have been around for a long time, the idea of a “precision” driver with a swivel top head for easy turning seems to be pretty recent. Klein Tools, for example, only introduced their precision tools in 2012.

Over the past several hundred years precision tools have gone from the very niche application with the making of pocket watches and jewelry to somewhat widespread for use in consumer electronics and phones. It will be interesting to see in the future how stronger materials and nanotechnology will come together to allow the manufacturing of even smaller and more precise tools.

Leave a comment